Unveiling the Secrets of Antenna Manufacturing in China: Discover the Techniques Shaping the Future!

Antenna manufacturing in China has emerged as a pivotal industry, playing a crucial role in the global supply chain for telecommunications, Internet of Things (IoT), and automotive sectors. As the demand for advanced communication technologies rises, so does the significance of antennas, which serve as the backbone for wireless communication. China, being the world's largest manufacturer of electronics, is at the forefront of this revolution, producing antennas that cater to a diverse range of applications. Understanding the processes involved in antenna manufacturing can provide insights into how these innovations are shaping our interconnected world, making it an essential topic for industry stakeholders and technology enthusiasts alike.

Understanding Antenna Manufacturing Processes

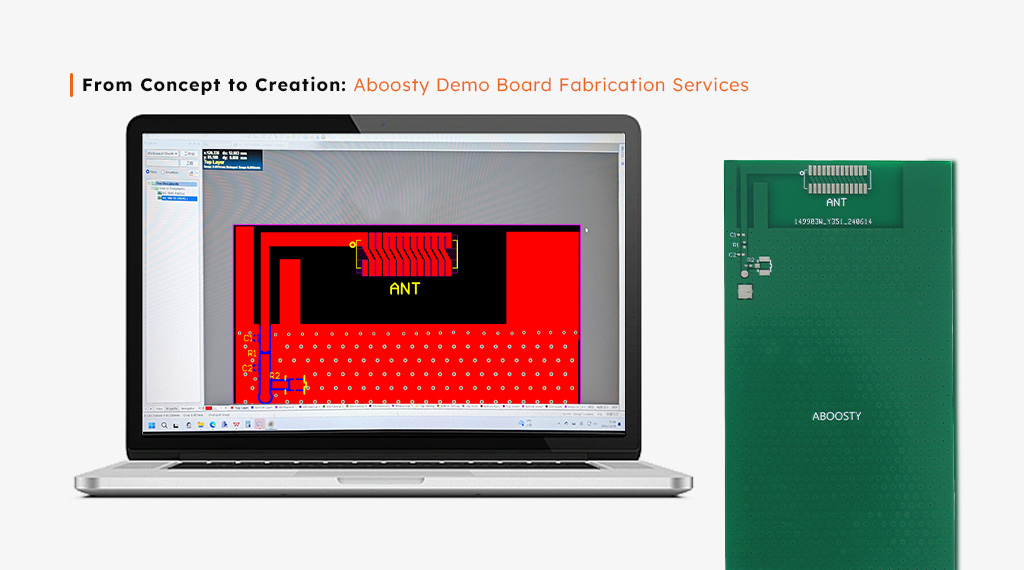

The process of antenna manufacturing is multifaceted, involving several key stages from design to production. Initially, the design phase is critical, where engineers utilize advanced simulation software to create models that meet specific performance criteria. These designs are then prototyped, allowing for real-world testing and iteration. Material selection is another vital aspect, with various materials chosen based on their electrical and mechanical properties to optimize antenna performance. The production methods employed can vary from traditional techniques to more modern approaches, but all aim to produce antennas that meet stringent industry standards and customer requirements.

Design Techniques

In the realm of antenna design, the use of simulation software has revolutionized the process. Engineers can now simulate electromagnetic fields and predict performance outcomes before physical prototypes are created. This not only accelerates the design cycle but also reduces costs associated with trial and error. Prototyping techniques, such as 3D printing, allow for rapid iteration and testing, enabling designers to refine their concepts in real-time. Furthermore, rigorous testing methodologies, including anechoic chamber tests and field trials, help ensure that the antennas perform as expected in various environments.

Materials Used in Antenna Production

The choice of materials in antenna manufacturing significantly impacts the overall performance and durability of the final product. Common materials include various metals like copper and aluminum for conductive elements, while dielectrics such as FR-4 and PTFE are used for substrates. Each material offers unique benefits—copper provides excellent conductivity, while FR-4 is cost-effective and widely used in printed circuit boards. The evolution of materials science continues to influence antenna design, with innovations such as lightweight composites and advanced coatings enhancing performance and longevity.

Advanced Production Techniques and Technologies

The landscape of antenna production is rapidly evolving, driven by technological advancements. Automation has taken center stage, with robotic arms and automated assembly lines increasing efficiency and precision in manufacturing processes. CNC (Computer Numerical Control) machining allows for intricate designs to be produced with high accuracy, reducing waste and improving turnaround times. Additive manufacturing, or 3D printing, is also making waves, enabling the production of complex geometries that traditional methods struggle to achieve. These advanced production techniques not only streamline operations but also foster innovation in antenna design and functionality.

Quality Control in Antenna Manufacturing

Quality control is paramount in the antenna manufacturing process, ensuring that products meet both regulatory standards and customer expectations. Manufacturers implement rigorous testing protocols throughout the production cycle, from raw material inspection to final product testing. Techniques such as automated optical inspection (AOI) and environmental testing help identify defects and ensure reliability. Continuous monitoring and feedback loops further enhance quality assurance, as data collected during production informs ongoing improvements and refinements.

Industry Trends and Future Outlook

The antenna manufacturing industry is currently experiencing transformative trends, particularly with the shift towards 5G technology. As telecommunications companies roll out 5G networks, the demand for specialized antennas that can handle higher frequencies and increased data throughput is surging. Additionally, the rise of smart devices and the IoT is pushing manufacturers to innovate, creating antennas that are smaller, more efficient, and capable of multitasking across various applications. Sustainability is also becoming a focal point, with manufacturers exploring eco-friendly materials and production methods to minimize environmental impact.

The Role of Innovation

Innovation is the lifeblood of the antenna manufacturing sector, driving advancements that redefine capabilities and performance. Emerging technologies such as Artificial Intelligence (AI) and Machine Learning (ML) are being integrated into design and production processes, enabling smarter and more adaptive antenna solutions. As new communication paradigms develop, the industry must remain agile, leveraging these innovations to address future challenges. The potential impact of these technologies is profound, paving the way for smarter cities, enhanced connectivity, and a more interconnected world.

Future of Antenna Manufacturing in China

In summary, understanding the antenna manufacturing process in China reveals the intricate techniques and technologies that are shaping the future of communication. From innovative design and material selection to advanced production methods and quality control, each aspect plays a vital role in the industry’s evolution. With the ongoing trends towards 5G, smart devices, and sustainability, the importance of this sector cannot be overstated. As we look to the future, the insights gained from examining these processes will be crucial for anyone involved in or affected by the rapidly advancing technological landscape.